Machines ready to serve You

Polypropylene production with quality and customers in mind

Who we are

As part of a larger network of companies and laboratories, we believe in innovation as the only solution to the complex challenge of the global market. Our processes, at FPT, are optimized to provide products that are perfectly in line with the customers’ needs. We believe in respecting the environment while we focus on green chemistry.

Thanks to our technical team, the acquired know-how, the skills of our people and the deep desire to innovate, we can develop in a very short time products that are tailored to our customers’ technical and workability requirements.

Main Markets

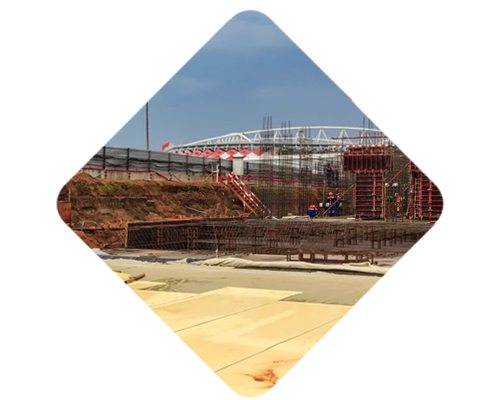

Polypropylene – Geo Textile Industry

Polypropylene has become a popular material in the geotextile industry due to its unique properties and versatility. Its excellent resistance to UV rays, acids, and alkalis, combined with its high strength and durability, make it an ideal material for use in various geotextile applications.

Polypropylene is commonly used in the manufacturing of geotextile fabrics that are used for erosion control, soil stabilization, drainage systems, and road construction. Its non-toxic and non-biodegradable nature makes it an environmentally-friendly option for geotextile products.

The low cost and ease of production of polypropylene geotextiles have made them a popular choice for construction and civil engineering projects.

The use of polypropylene in geotextile products has contributed to improved infrastructure, reduced environmental impacts, and increased safety in the construction industry.

Polypropylene - Hygiene Industry

Polypropylene is widely used in the hygiene industry due to its unique properties and low cost. Its excellent moisture resistance, durability, and high tensile strength make it an ideal material for a wide range of hygiene applications.

Polypropylene is commonly used in the production of personal hygiene products, including disposable diapers, sanitary pads, and adult incontinence products. It is also utilized in the manufacturing of medical gowns, masks, and caps. Polypropylene’s hydrophobic properties and high barrier performance make it an excellent choice for packaging materials for personal care and hygiene products, such as wet wipes, tissues, and feminine hygiene products. Its lightweight, non-toxic, and easy-to-process nature have made it a popular choice in the hygiene industry, contributing to the overall safety and comfort of consumers.

Polypropylene - Automotive Industry

Polypropylene, a thermoplastic polymer, has gained widespread use in the automotive industry due to its unique properties. Its excellent chemical resistance, high-temperature tolerance, and low density make it an ideal material for various applications in the automotive sector.

Polypropylene is commonly used in the manufacturing of automotive interior parts, such as dashboard panels, door trims, and seat components. It is also utilized in the production of exterior components like bumpers, fender liners, and grilles.

Additionally, polypropylene is used in under-the-hood applications, including engine covers and air intake systems, due to its ability to withstand high temperatures and exposure to chemicals. Its durability, lightweight, and low production cost have made it a popular choice in the automotive industry, contributing to the overall efficiency and safety of vehicles.

Polypropylene - Filtration Industry

Polypropylene is widely used in the filtration industry due to its excellent chemical resistance, high-temperature tolerance, and low cost. Its unique properties make it an ideal material for use in various filtration applications, including water treatment, air filtration, and chemical processing.

Polypropylene is commonly used in the manufacturing of filter cartridges, filter bags, and filter membranes. Its hydrophobic nature makes it an excellent material for water filtration applications, as it repels water and allows for high filtration rates. Polypropylene filter media can also withstand high temperatures and chemical exposure, making it ideal for use in industrial processes.

The low cost and ease of production of polypropylene filters have made them a popular choice in the filtration industry, contributing to improved efficiency, safety, and environmental performance in various applications.